Nationwide Vehicle Contracts takes a look at the science behind car designs and how aerodynamics affects performance

Manufacturers are constantly battling to produce good-looking yet well-performing cars regarding aerodynamics. The key to the high trend in product quality was the balance between art and science. Car designers didn't spend nearly as much time working out aerodynamics, safety, and fuel efficiency 20 years ago as they do in modern times, with science now playing a much more significant role in automotive design.

Plus, with the cost of petrol and diesel rising and the electric car industry growing, car manufacturers are taking more and more care in designing their cars to be more fuel efficient. Below we explore everything to do with a car's design and how aerodynamics affects its performance.

What Is Aerodynamic Drag?

Aerodynamic drag on a car is the force it needs to overcome as it moves through the air at a certain velocity. It is the resistance offered by the air to the car body's movement. So, when a car is moving, it displaces the air and affects its speed and performance.

Manufacturers constantly work to reduce aerodynamic drag to the absolute minimum as it has a negative effect on the vehicle's performance and efficiency. For example, a car with an upright stance has a drag coefficient of 1.30, whereas a car with a raindrop design shape has the least amount of drag. The average drag coefficient for cars nowadays is 0.40, but some models with the best aerodynamic design have as low as 0.26.

The reduction in drag can help decrease a vehicle's wind/air resistance, which can help increase fuel efficiency to some extent. However, it also enhances other aspects of a car's performance, such as handling and acceleration. The two main elements that affect the overall drag effect are the vehicle's frontal area and the drag coefficient.

Wind tunnels

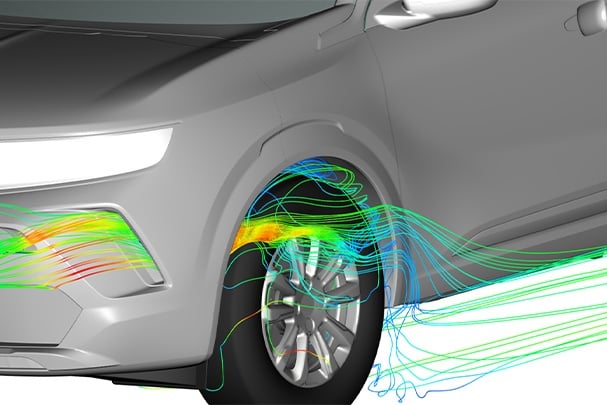

Manufacturers use wind tunnels to test the behaviour of their vehicle prototypes. The car is anchored down, and a stream of air is blasted past it in a wind tunnel to replicate the conditions it would encounter when driven. Below is an example of the Vauxhall Corsa getting tested in a wind tunnel.

The vehicle is equipped with sensors that measure the amount of lift or downforce produced at each end of the vehicle. By sticking little tufts of wool to the car's body or blowing a stream of smoke past it, the passage of air past the vehicle can be seen.

The wool or smoke's behaviour reveals the direction the wind follows as it passes over the car. The behaviour of the air in front of and behind the vehicle is also visible in the smoke. Woollen tufts organise themselves according to the airflow over the car's body, but they cannot portray how the air behaves in front of or behind the vehicle.

The vehicle can also be rotated around at different angles in the wind tunnel so that the engineers can observe how the body shape responds to side winds.

How to reduce the Aerodynamic Drag?

You can lower the drag by streamlining the vehicle's exterior body. Character lines must be used to streamline the body and precise calculation of the surrounding airspeed. In some high-speed cars, manufacturers attach a rear spoiler to the boot to significantly reduce the drag.

To further minimise aerodynamic drag, manufacturers use character lines on the exteriors of the car's body right from its concept stage. These lines help the air to pass smoothly over the body, reducing air resistance.

To eliminate the aerodynamic drag, Manufacturers often work on the exterior components such as the windscreen wipers, radio antenna, side mirrors, mud flaps, and rear spoiler, among others. They also redesign the front bumper, partial front grille, under-body trays, fender skirts, wheel covers, rear boot, etc.

For more information, check out our Understanding Car Size and Dimensions and Understanding Car Body Types guides.

Find out more about Car Leasing by calling Nationwide Vehicle Contracts on 0345 811 9595 to speak to one of our skilled leasing specialists about the right option for you.

Originally posted: 16th February 2023